-

- Scalable Porosity

- Adaptive Environments

- Kite-powered Design-to-Robotic-Production

- Fibrous Smart Material Topologies

- S.M.A.R.T Environments

- Robotic Building

- METABODY

- --- METABODY 1st EVENT

- --- METABODY 2nd EVENT

- --- Hyperbody update 02-2014

- --- Hyperbody Msc2 prototypes

- --- Ambiguous Topology 07-2014

- --- Reflectego & RoboZoo 07-2014

- --- The Hyper-loop

- --- Nervion, Textrinium & [S]caring-ami 07-2015

- SynSerre

- Robotic Architecture

- Automotive Complex

- Space-Customizer

- InteractiveWall

- iLITE

- Manhal Oasis Masterplan

- Muscle NSA

- protoCITY 2005+

- Virtual Operation Room

- Digital Pavilion

-

-

-

- Projects

- Kite-powered Design-to-Robotic-Production

- Year / Period

- 2016-2020

- Project Leaders

- Henriette Bier and Roland Schmehl

- Project team

- RB and KP teams from Faculties of A&BE and and AE, respectively

- Collaborators / Partners

- Delft Robotics Institute (DRI), 100% Research TUD, PIMM lab, ABB, KUKA, Green Village

- Links

- Robotic Building

Kite Power

-

-

Kite-powered Design-to-Robotic-Production

Design-to-Robotic-Production as developed by the Robotic Building team at TUD employs customised design to production processes that incorporate material properties in design, control all aspects of the design to production process numerically, and utilise parametric design principles that can be linked to the robotic production. The main consideration is that in architecture and building construction the factory of the future employs building materials and components that can be robotically processed and assembled.

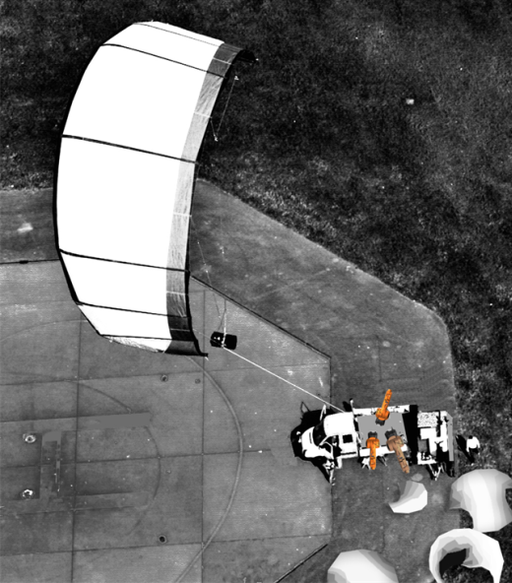

When coupled with the electricity generating Kite Power System (KPS) developed at TUD, the D2RP unit becomes a mobile sustainable autarkic unit that can be deployed everywhere. The D2RP system together with the KPS developed at TUD allows for ad hoc set-up and operation anytime and everywhere with minimal infrastructure. It is based on a generic methodology relying on a robust, scalable, yet highly flexible technology. The assumption is that when such customisable fabrication set-up is provided to users in order to address local needs and conditions, users can easily customize processes employing local materials and parametric designs. This assumption will be tested by building a 1:1 prototype in the Green Village are of the TUD campus.

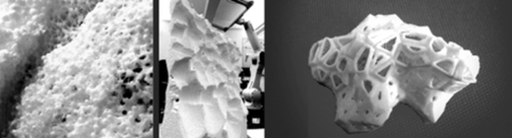

- Fig.1: From micro (material) to mezzo (components) and macro (architectural) scale experiments for student housing project

The societal challenge that the kite-powered robotic building system aims to address is building affordable, material- and energy-efficient housing with D2RP methods powered by sustainable KPS. The assumption is that D2RP technologies counter negative effects of globalization and maximise the role of local human re-sources and construction materials by using new, customisable, open-source procedures. Material usage is minimized, since design to production optimizes the use of materials quantitatively and performance-wise. Novel materials and multi-material compounds, which allow the construction of building components with a. o. robotic additive (3D printing) and subtractive technology, are developed. Together with structural optimizations during the design process, this technology enables building components with the minimal quantity and the right quality of materials to perform the integrated functions of the components.

The prototype of approx. 9/3/3 m will be designed and built with MSc students guided by researchers from ABE and AE. Materials considered are polymer- and cement-based materials combined with wood. Robotic techniques used will be additive, subtractive, and transformative. Several robots will be employed at the same time.

- Fig. 2: Impression KP D2RP operated in situ KPS

Employed D2RP processes enable production of free-formed, heterogeneous, optimized structures by addi-tively and selectively depositing or manipulating materials in order to achieve specific porosity-density, flexibility-rigidity, etc. requirements in accordance to formal, functional, structural, climatic, environmental, and economic needs. They require multi-robot production implying that several robots operate simultaneously or in short sequence in the process of production and assembly of multi-material building components. This is necessary in order to, for instance, deposit reinforcement fibres or granular insulation material, etc. in parallel to depositing cement-based materials, etc.

This kite-powered robotic building system will contribute to the affordable housing problem by connecting the robust and highly reliable industrial robotics technologies with the local production approaches. This will lead to the development of products and processes for the building market, both providing sustainable means of habitation and the possibility for jobs and technical training in the field of D2RP. Considering that D2RP methods cut production costs more than 40% and delivery times to 100% percent, while additional savings are achieved by increasing material and energy efficiency (through structurally and climatically informed material deposition) this research presents an approach to affordable housing that can be applied anytime everywhere. In this context, kite-powered robotic building is creating impuls for economic activity with low-cost, easy-to-operate tools.

Acknowledgements

This project has profited from the input of Hyperbody researchers and students teams and is based on the Robotic Building framework developed by the main author 2010-13. It has furthermore profited from input from Kite Power and Robotic Building teams. Kite Power has been supported by EU and Robotic Building has been supported 2014-16 by 3TU, Delft Robotics Institute (DRI), 100% Research, AE&T, KUKA, and ABB.

Facebook/

Facebook/

Twitter/

Twitter/

RSS

RSS