SynSerre2 project (Synergetic Greenhouse)

Hans Hubers

On April 29 2011 a team of experts from Delft University of Technology and Wageningen UR (University & Research centre) started a collaborative design in Hyperbody's protoSPACE lab.

It will become a prototype greenhouse that produces energy and food while reducing the heat loss of an existing building at the Campus of Delft. For Delft are participating: Prof. Ir. Kas Oosterhuis (Hyperbody, Faculty of Architecture), Prof. Dr. Ir. Andy van der Dobbelsteen and Ir. Kees van der Linden (Climate Design & Sustainability, Faculty of Architecture), Prof. Dr.-Ing. Patrick Teuffel (Architectural Engineering, Faculty of Architecture), Prof. Dr. Ad van Wijk (Energy, Faculty Applied Sciences), Ir. Eric van den Ham (Building Physics, Faculty of Architecture). For Wageningen UR participates Dr. Piet Sonneveld, project leader of greenhouse prototypes that turn the Near Infrared Radiation, which is not useful for plants into electricity and heat. Dr. Ir. Hans Hubers (Hyperbody, Faculty of Architecture) will lead the SynSerre project.

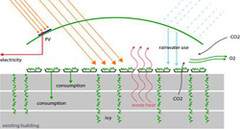

According to the CBS statistics, greenhouses in 2008 used 4% of the fossil fuel in the Netherlands. Research of Wageningen UR shows that innovations for greenhouses have a return of investment of seven years at best if the gas price would double to 45 eurocent per m3. A radical new concept is needed. It is a general rule that 1% of extra light results in 1% of extra tomatoes and that sort of products. An open sunny place would be best in that respect, but a cover is needed to keep harmful insects out and useful insects in and to protect against cold and hail. Also an augmented CO2 level from 350 to 1200 ppm gives about 35% higher production. ETFE foil has the highest light transmittance, but one layer doesn't insolate enough heat loss and is rather fragile. Double layered cushions could solve this, but are expensive and reduce the light transmittance below that of anti-reflection coated glass. Most of the undesired heat loss is during the night and on cold cloudy days. Movable insolation screens are therefore much used in greenhouses, but cause problems with condensation. A level of around 1200 ppm CO2 is preferable for the photosynthesis, but during sunny days windows are opened to prevent for overheating, adding to the global warming problem instead of reducing it. A closed system is needed. Enough problems that ask for a collaborative interactive design solution. That's why Hyperbody takes the lead. A SynSerre prototype at the campus is the best way to convince parties to invest in this development.

The heating and cooling of buildings is responsible for 40% of the total energy use and CO2 emission. Attaching a SynSerre to the building, e.g. the roof, reduces the heat loss of the existing building and at the same time reduces the cost of foundation and land for the greenhouse. Sincerely a synergetic solution! But will greenhouse farmers move to the roofs of buildings? Will transport of products be a problem? Can we combine with other functions? What will be the overall yearly cost and income of a SynSerre? Only a well-designed SynSerre prototype can answer these questions.

Facebook/

Facebook/

Twitter/

Twitter/

RSS

RSS